Hercules has spent many years developing solid relationships with more than ten high quality manufacturers around the world, based in Europe, Asia and the USA.

As a result, the technologies we can provide are ground-breaking, highly innovative and in many cases beyond what our competitors are able to accomplish as sole manufacturers.

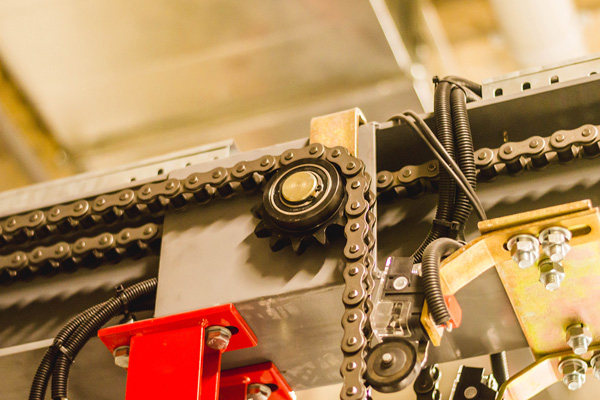

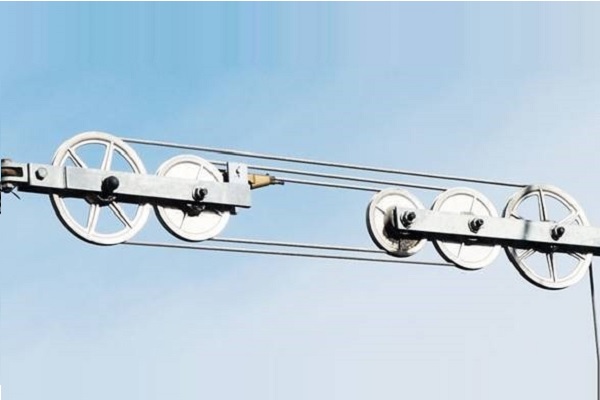

Behind every car stacker system are the system components. Our suppliers are committed to the development and manufacture of high-performance components, concentrating on those relevant to machine function and safety. We understand that efficient and sustainable technologies are critical.